Before you inspect the engine compartment and front axle components, it is crucial to prioritize safety and have a clear understanding of the components and their functions. This comprehensive guide provides a step-by-step approach to ensure a thorough and effective inspection process, empowering you to identify potential issues and maintain the optimal performance of your vehicle.

By following the detailed instructions and utilizing the provided visual aids, you will gain the confidence to conduct a comprehensive inspection, ensuring the safety and reliability of your vehicle.

Safety Precautions

When working on an engine compartment and front axle components, it is essential to prioritize safety. Adhering to proper safety precautions minimizes the risk of accidents and ensures a safe working environment.

- Wear proper safety gear:Always wear safety glasses, gloves, and appropriate clothing to protect yourself from potential hazards such as fluids, sparks, or moving parts.

- Ensure a clean and well-lit work area:A clean and well-lit workspace allows for clear visibility and reduces the risk of tripping or slipping.

- Disconnect the battery:Before beginning any work, disconnect the battery to prevent electrical shocks or accidental starting of the engine.

Identifying and Locating Components

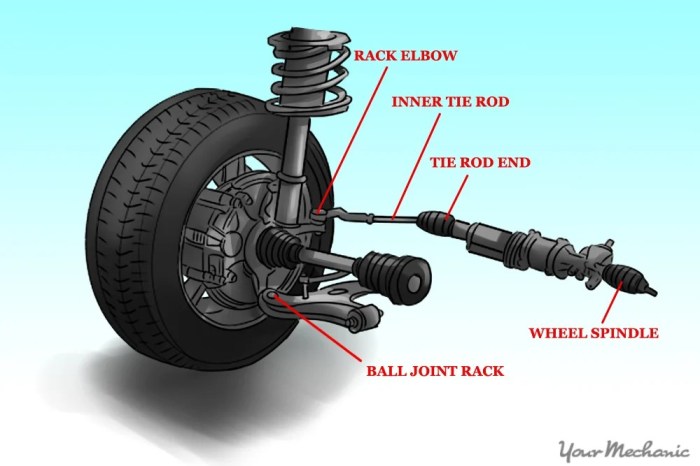

To effectively inspect the engine compartment and front axle components, it is crucial to identify and locate them accurately.

| Component | Location | Function | Notes |

|---|---|---|---|

| Engine | Front of the vehicle | Provides power to the vehicle | Check oil level and condition regularly. |

| Radiator | In front of the engine | Cools the engine coolant | Monitor coolant levels and flush regularly. |

| Battery | Typically in the engine compartment | Provides electrical power to the vehicle | Keep terminals clean and connections tight. |

| Alternator | Mounted on the engine | Charges the battery and powers electrical systems | Check belt tension and electrical connections. |

| Steering rack | Front of the vehicle, behind the wheels | Controls the direction of the vehicle | Inspect for leaks and loose connections. |

| Front suspension | Connects the wheels to the vehicle’s body | Provides stability and handling | Check for worn or damaged components. |

Visual Inspection Techniques

Visual inspection is a crucial step in identifying potential issues with engine compartment and front axle components.

- Check for leaks:Look for any visible signs of fluid leaks, such as oil, coolant, or brake fluid, around components and hoses.

- Inspect for corrosion:Examine metal components for signs of corrosion, such as rust or pitting, which can weaken the component and lead to failure.

- Check for loose connections:Ensure that all electrical connections, hoses, and belts are securely fastened and not loose or damaged.

- Look for visible damage:Inspect components for any visible damage, such as cracks, dents, or broken parts, which may indicate a need for repair or replacement.

Functional Tests

In addition to visual inspection, functional tests can help assess the performance of engine compartment and front axle components.

- Belt tension test:Check the tension of belts, such as the serpentine belt or timing belt, using a belt tension gauge.

- Hose leak test:Pressurize the cooling system or power steering system to check for leaks in hoses and connections.

- Electrical system test:Use a multimeter to test electrical connections, such as battery voltage, alternator output, and ground connections.

- Steering system test:Check the steering rack for leaks, loose connections, and proper alignment.

- Suspension system test:Inspect the suspension components for wear or damage, and check the alignment of the wheels.

Documentation and Reporting

Documenting inspection findings is essential for tracking maintenance history and identifying potential issues early on.

- Create a detailed report:Include observations, test results, and recommendations for any repairs or replacements.

- Use digital photos:Take pictures of any visible damage or issues to provide visual documentation.

- Maintain inspection records:Keep a record of all inspections and repairs performed on the vehicle for future reference.

Answers to Common Questions: Before You Inspect The Engine Compartment And Front Axle Components

What are the essential safety precautions to consider before inspecting the engine compartment?

Wear appropriate safety gear, ensure a well-lit and clean work area, and disconnect the battery to prevent electrical hazards.

How can I identify and locate the major components of the engine compartment and front axle?

Refer to the provided HTML table that lists and describes the components, including their location, function, and relevant notes.

What are the key visual inspection techniques to look for when examining engine compartment components?

Check for leaks, corrosion, loose connections, and any visible signs of damage. Follow the step-by-step guide provided for a thorough inspection.

What functional tests can be performed on engine compartment and front axle components?

Conduct tests for belts, hoses, and electrical systems as described in the guide. Understand how to interpret the results to assess component functionality.

Why is it important to document inspection findings and create a detailed report?

Documentation helps track inspection history, provides evidence of maintenance, and facilitates future repairs by providing a clear record of observations, test results, and recommendations.